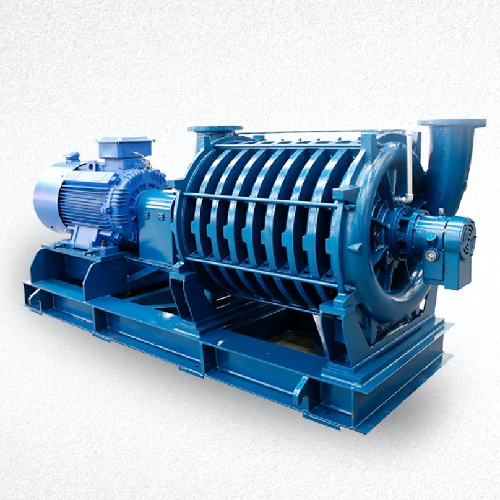

- model: MC series casting multi-stage centrifuge

- Availability: 2025-06-12

- category: Sewage treatment plant

- intro: The MC series found multi-stage centrifuges developed by my company for the introduction of United States technology, and with the use of proprietary or proprietary technologies, have a clear advantage over domestic products in terms of low noise, low vibration and efficiency. Product Overview 1. Wind-in-air exhaust case and backstream

Driving machines

The MC series found multi-stage centrifuges developed by my company for the introduction of United States technology, and with the use of proprietary or proprietary technologies, have a clear advantage over domestic products in terms of low noise, low vibration and efficiency.

Product Overview

1. Wind-in-air exhaust casings and refluxors are fully compatible with leaf wheels through the optimization of parameters, and the fluid-type design flow loss is even smaller.

2. Implementation of tri-channel noon, modular leaf wheels, complex line technology, and high-efficiency of voltage gas.

3. The lack of a guidance loop for the import of leaf wheels has effectively improved their liquidity.

4. Wing-type reflower foliage design technology, with small losses and higher pressure conversion.

5. The application of mobile analysis technology optimizes the performance of the wind transmitter, which is more than 78 per cent volatile.

6. The same blower meets the speed of 50 Hz and 60 Hz, and the winder adjusts to a wide range and performance.

7. The rotor, after a strictly tuned balance, has a small vibration, high reliability and low overall noise.

8. The co-located floors can be fitted with shock-mitigating pads that are fixed without a foot bolt, save time and effort and reduce the cost of basic production.

9. Wind machines are well-structured and well-structured, have few vulnerable items and are easily installed, operated and maintained.

Main uses

Water treatment, wastewater treatment, biogas recovery, vacuum dust removal, gas blade drying, float and mine selection, zinc plating and electroplating, oxygen filling of liquids and baths, process gas transport, paper and printing industries, air combustion (defurinization, carbon black, furnace smelting, etc.).

English

English Pусский

Pусский 中文

中文