- model: Loop dryer

- Availability: 2025-06-12

- category: Sludge incineration plants

- intro: The company introduced the manufacturing and system integration technology of the Mitsubishi material drying and disposal core equipment in response to current developments in material minimization, neutralization, stabilization and resourceization. In combination with the state of the material, two sets of disk dryers, SDK and FDK, were developed. The main body of the disk dryer is mainly a set, rotor and driver group.

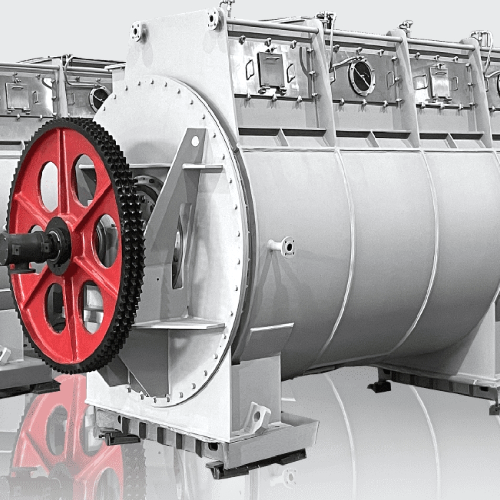

Disk dryer

The company introduced the manufacturing and system integration technology of the Mitsubishi material drying and disposal core equipment in response to current developments in material minimization, neutralization, stabilization and resourceization. In combination with the state of the material, two sets of disk dryers, SDK and FDK, were developed.

The main subject of the dryer of the disk consists mainly of the fixed, rotor and drive:

Zero: The fixed shape of the disc dryer is similar to that of a cylinder, with a dome at the top, a volume space for carrying air and water vapour, and a waste gas export and re-entry to facilitate equipment maintenance and overhaul. The slabs are installed in Frank to facilitate their repair, while the slabs are also used to fix the bearings of the rotor.

The rotor: is the carrying part of the whole dryer, consisting of a medium axle and a medium-empty disk. In order to enhance the robustness of the disk, the hollow inner cavity sets up several support poles by ring. The outer edge of the disk is fitted with a propulsion/mixer, while acting as a propulsion and mixing material.

Drivers: Composed of embedded speed-reducing boxes, chain wheeling, couplings, electrics, etc., to drive the slow rotation of the rotor.

English

English Pусский

Pусский 中文

中文